Enhancing Packaging Performance: Exploring the Advantages of High Barrier Metallized CPP Film

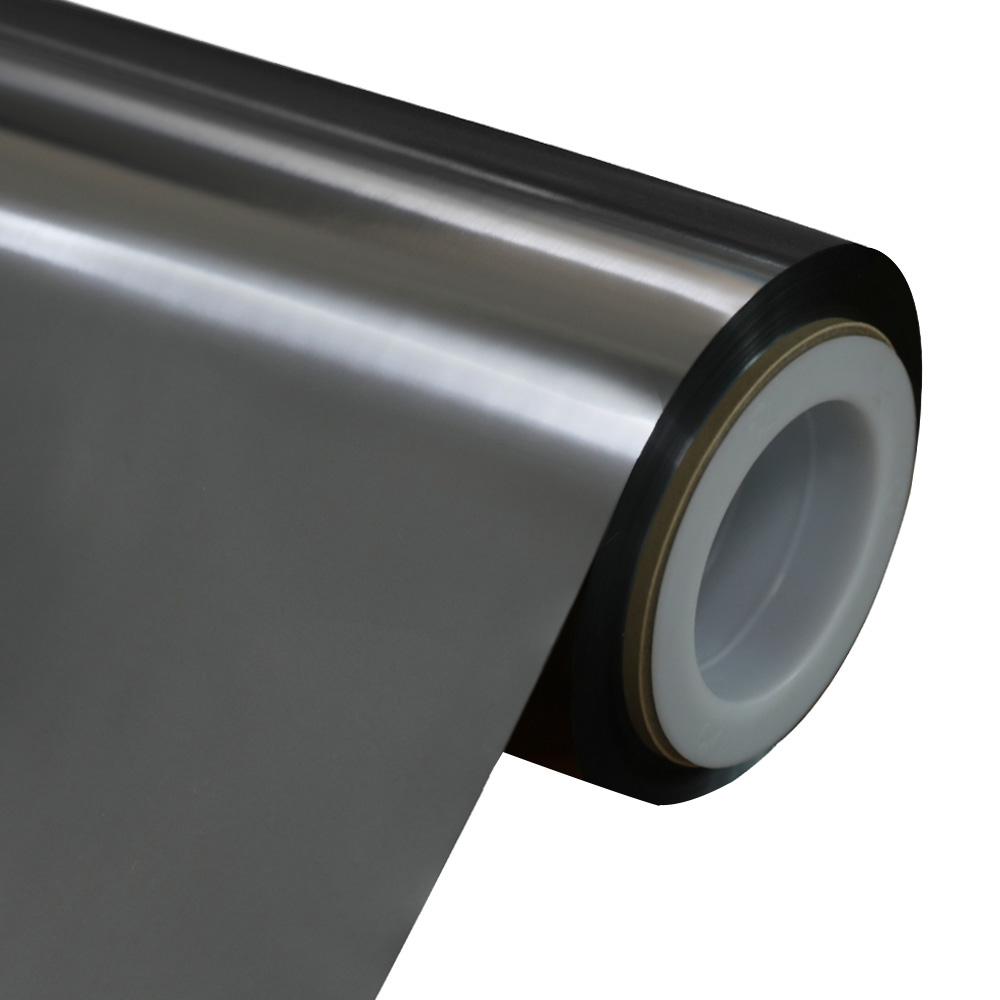

In the world of flexible packaging, innovation plays a crucial role in meeting the demands of preserving product freshness, extending shelf life, and ensuring product safety. High barrier metallized CPP (Cast Polypropylene) film has emerged as a game-changer in the packaging industry. In this article, we delve into the world of high barrier metallized CPP film, exploring its properties, benefits, and its role in enhancing packaging performance for a wide range of products.

Understanding High Barrier Metallized CPP Film:

High barrier metallized CPP film is a multi-layered packaging material that combines the advantages of cast polypropylene film with a metallized layer. The metallization process involves depositing a thin layer of metal, typically aluminum, onto the CPP film surface. This creates a barrier that provides exceptional protection against moisture, oxygen, light, and other external factors that can compromise product quality and freshness.

Advantages of High Barrier Metallized CPP Film:

Excellent Barrier Properties:

The primary advantage of high barrier metallized CPP film is its exceptional barrier properties. The metallized layer acts as an effective barrier against moisture vapor transmission, oxygen permeation, and UV light, helping to preserve the freshness, flavor, and aroma of the packaged products. This is particularly beneficial for perishable items, such as food, beverages, pharmaceuticals, and sensitive electronic components.

Extended Shelf Life:

By significantly reducing the ingress of oxygen and moisture, high barrier metallized CPP film helps to extend the shelf life of packaged products. This is critical for products that require long-term storage or transportation, allowing manufacturers and retailers to ensure product quality and minimize waste.

Product Protection:

The barrier properties of high barrier metallized CPP film offer reliable protection against external factors that can negatively impact product quality. It helps to safeguard against moisture-related issues like spoilage, mold growth, or chemical degradation. Additionally, the barrier properties protect sensitive products from UV light, which can cause color fading or degradation of certain substances.

Enhanced Product Visibility:

High barrier metallized CPP film allows for product visibility and presentation. The metallized layer provides a reflective surface that enhances the visual appeal of the packaging, making it attractive to consumers. This is particularly beneficial for products that rely on visual appeal, such as snack foods, confectioneries, or personal care items.

Lightweight and Flexible:

High barrier metallized CPP film is lightweight and flexible, making it an ideal choice for flexible packaging applications. Its flexibility allows for easy packaging of irregularly shaped products, while its lightweight nature helps to reduce transportation costs and environmental impact.

Heat Sealability:

High barrier metallized CPP film offers heat sealability, ensuring secure and tamper-evident packaging. It can be easily heat-sealed to create a strong and hermetic seal, protecting the contents from contamination and maintaining product integrity.

Applications of High Barrier Metallized CPP Film:

High barrier metallized CPP film finds applications in various industries, including:

Food Packaging:

High barrier metallized CPP film is widely used in food packaging, including snack foods, coffee, tea, dried fruits, biscuits, and confectioneries. It helps to preserve the freshness, aroma, and flavor of food products while providing an attractive and shelf-ready packaging solution.

Pharmaceuticals and Healthcare:

In the pharmaceutical and healthcare industries, high barrier metallized CPP film is utilized for packaging pharmaceuticals, medical devices, diagnostic kits, and healthcare products. The barrier properties of the film protect the sensitive contents from moisture, oxygen, and light, ensuring product efficacy and stability.

Electronics and Electrical Components:

High barrier metallized CPP film plays a vital role in the packaging of electronic and electrical components, such as integrated circuits, semiconductors, and sensitive electronic devices. It provides protection against moisture and static charges that can damage the components during storage or transportation.

Personal Care and Cosmetics:

The barrier properties and visual appeal of high barrier metallized CPP film make it a popular choice for packaging personal care and cosmetic products. It ensures product freshness, protects against external factors, and enhances the visual presentation of the products.

High barrier metallized CPP film offers a range of advantages that enhance packaging performance and product protection. Its barrier properties, extended shelf life capabilities, product visibility, lightweight nature, and heat sealability make it an ideal choice for various industries, including food, pharmaceuticals, electronics, and personal care. As the demand for effective and reliable packaging solutions continues to grow, high barrier metallized CPP film provides a versatile and innovative option to meet the evolving needs of manufacturers, retailers, and consumers alike.

English

English  中文简体

中文简体