Established in April 2000, Zhejiang Changyu New Materials Co., Ltd. is a professional

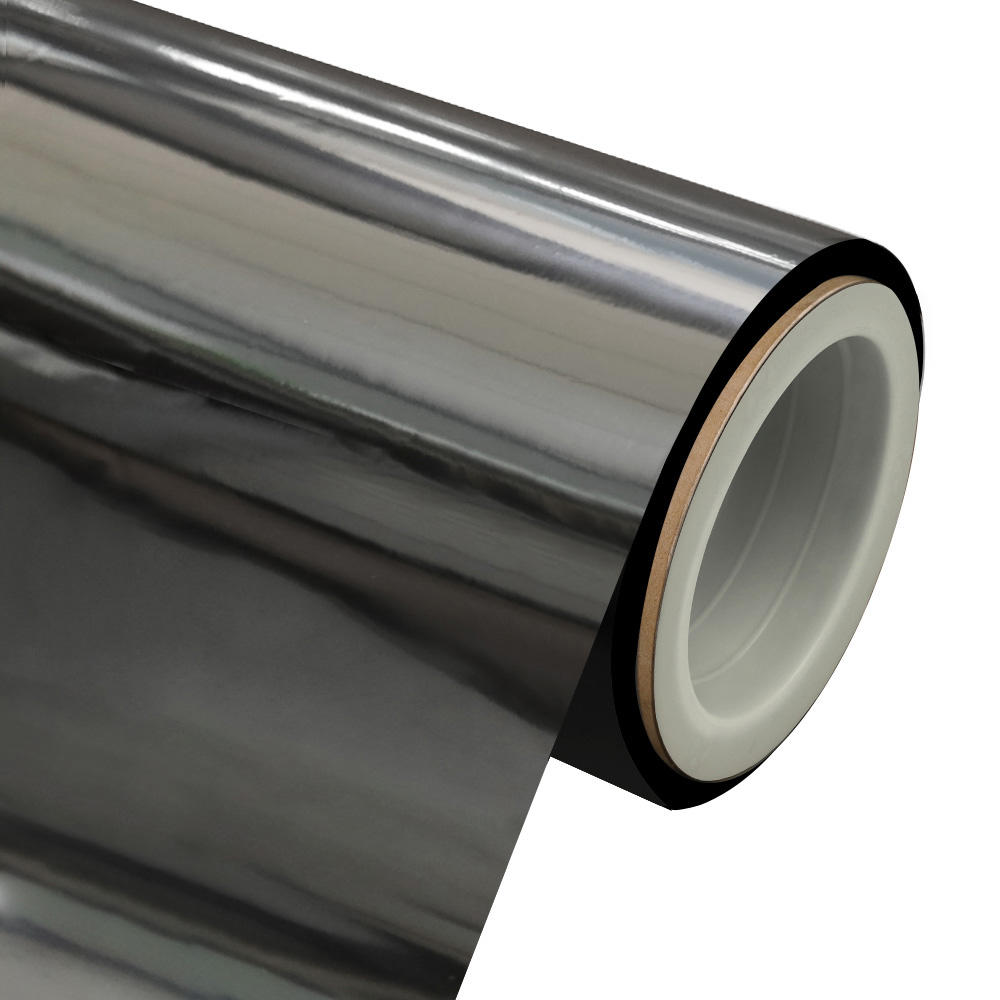

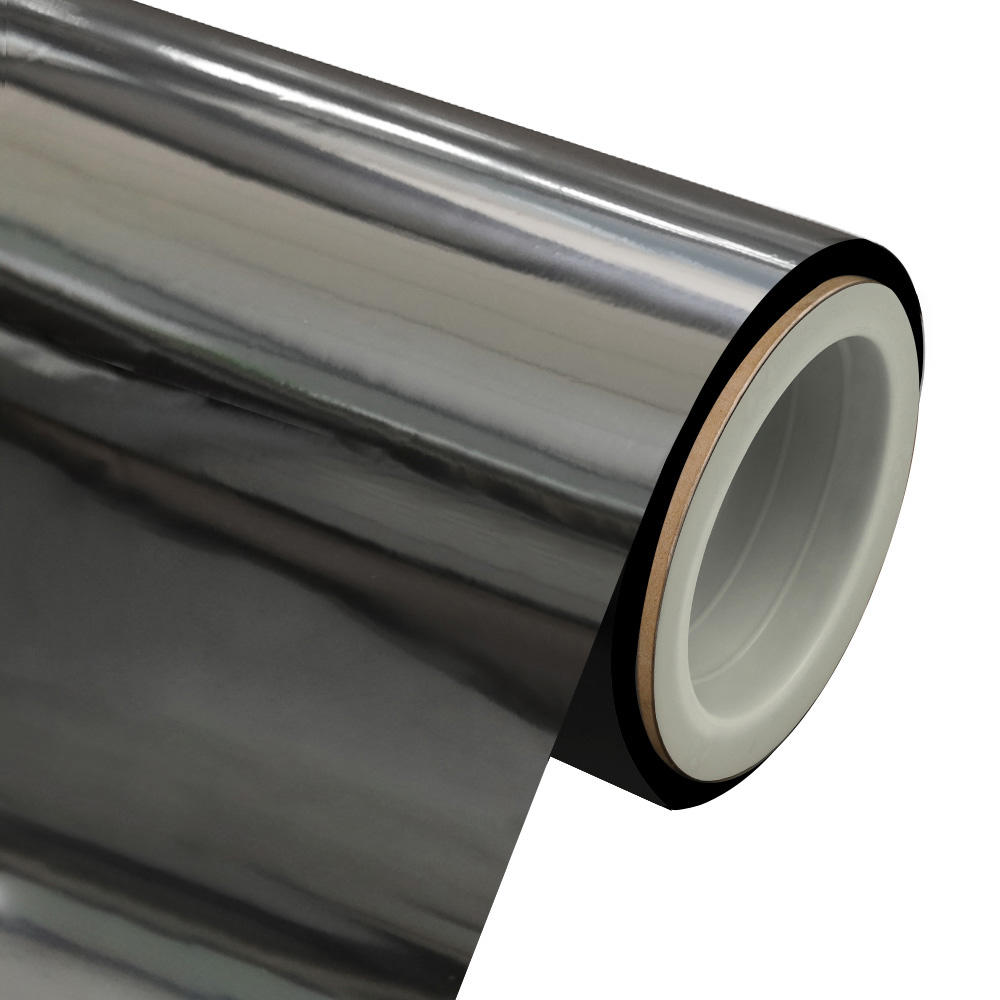

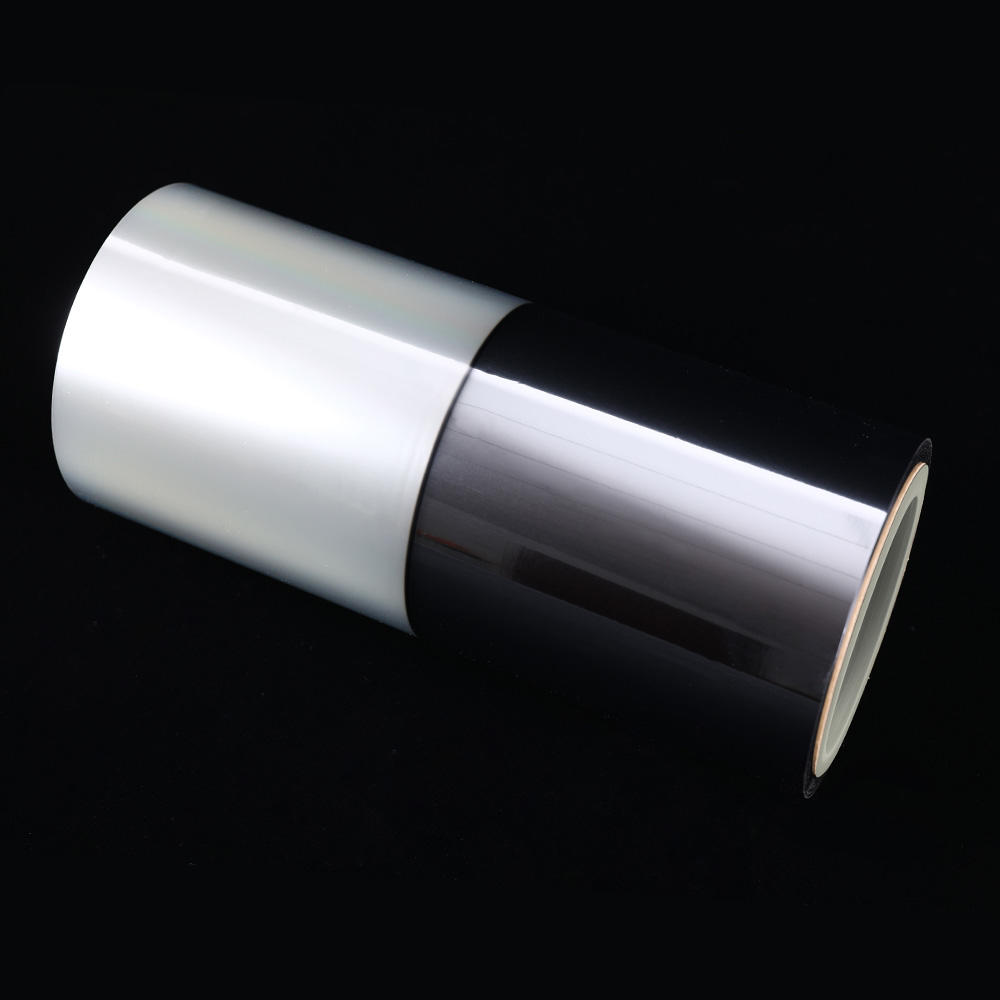

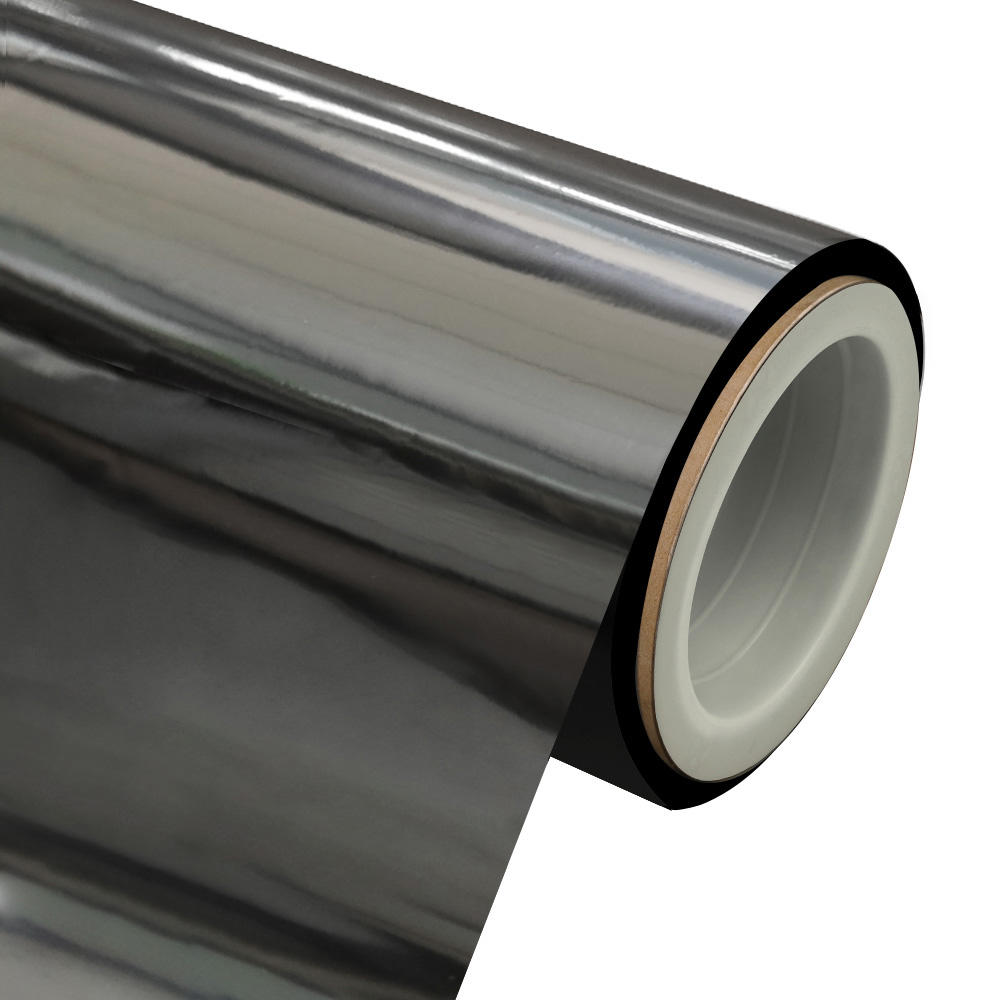

China Aluminized PET Films Manufacturers specializing in

Wholesale Aluminized PET Films . We keep stable cooperation with famous enterprises like Amcor, Bemis, Zijiang.

As a professional

Aluminized PET Films Factory, we have about 350 employees and the factory covers an area of 40,000 square meters. With 16 metallizing equipment and 5 coating equipment, our annual output is 100,000 MT various metallized film and 8,000 MT coated film. The introduction of alumina equipment and crucible metalizer from Germany are committed to the development of high-end products. Our main products include VMPET, VMCPP, VMBOPP, PVDC coated film, Acrylic coated film, ALOx PET film.

Changyu is the pioneer and advocator of "transparent aluminum oxide film for packaging" in the Chinese market, we have made unremitting efforts for the development and promotion of this product, changyu is also the consitutor of ongoing major national standard project" Quality general rules of oxides barrier transparent plastics laminated films and pouches for food packaging".

After years’ development, Changyu’s

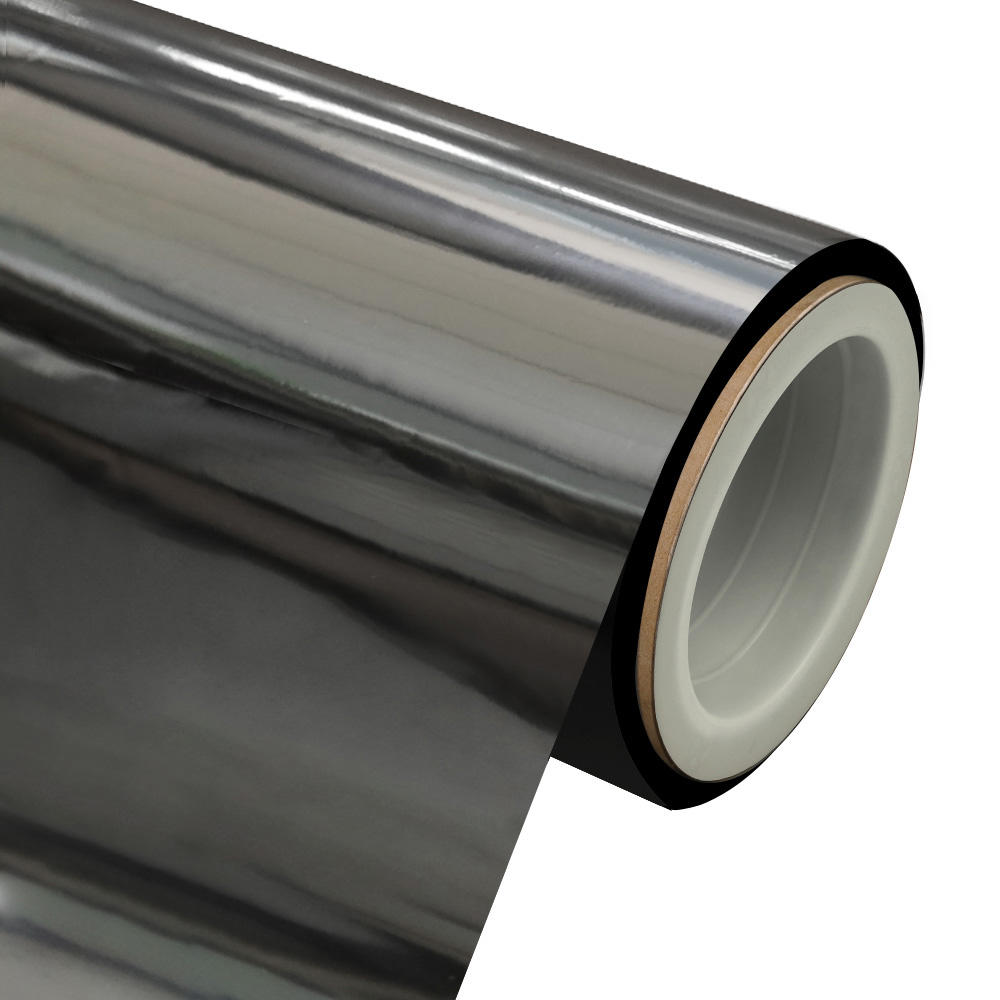

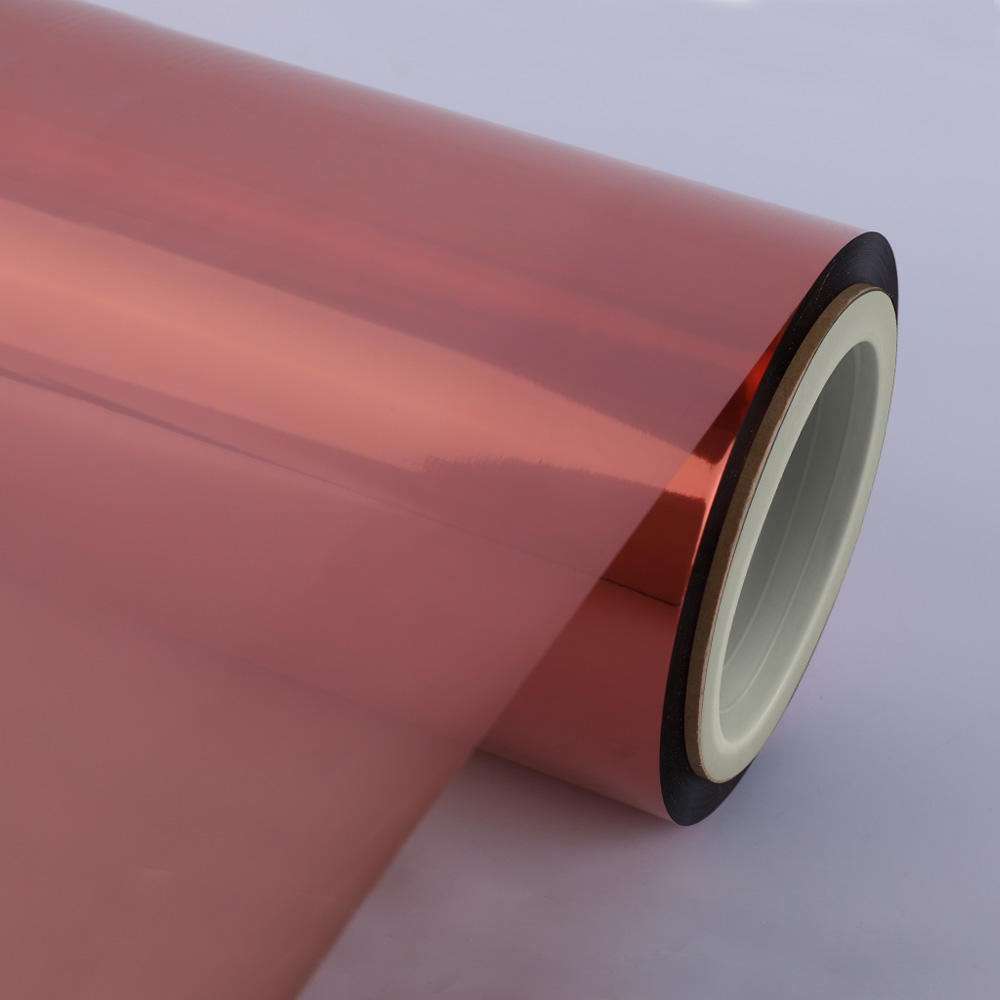

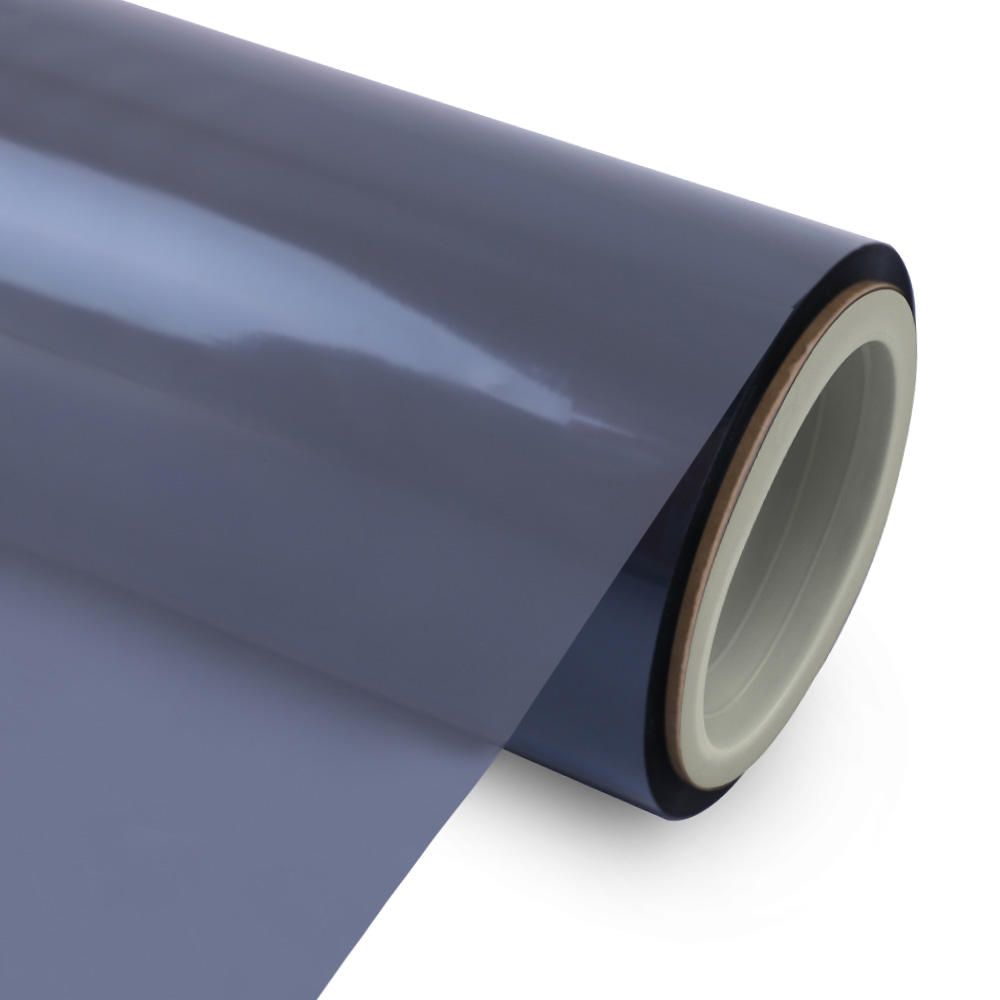

VMPET-T11N12-P01-GD(Color Coated Metallized PET Film)Chemical Treated Metallized PET FilmPH12-SEMI100/150(Semi Metallized PET Film)PH-P01-S(Both Sides Corona Treated Metallized PET Film)NCTW(Metallized Twist PET Film)NC12-P01-PAR(Partial Metallized PET Film)PH-P02(High Barrier Metallized PET Film)NC-P01(Normal Metallized PET Film), also export to Southeast Asia, Europe, America and other international markets. With technology and professional cooperation, Changyu has won good reputation in the market.

In 2013, Changyu was awarded the title of National High-tech Enterprise based on more than 100 utility model patents and multiple invention patents. We have passed the ISO9001 by BSI from British, and the testing of the SGS, FDA.

Adhering to the concept of "being a century enterprise", Changyu absorbs the advanced production technology and management experience at home and abroad in an open spirit, keeps creating value and giving back to the society.

English

English  中文简体

中文简体