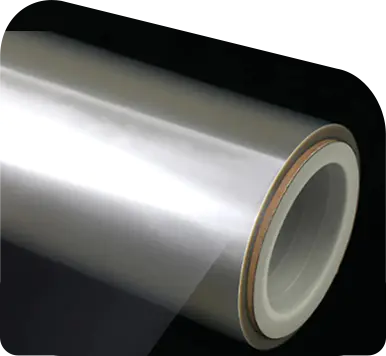

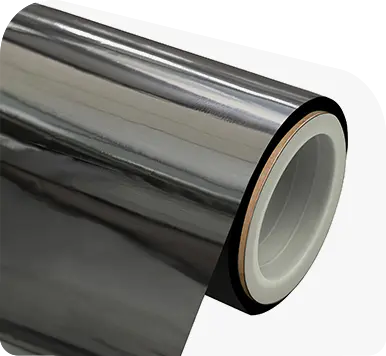

Recommended product

Main Products

Understand Us

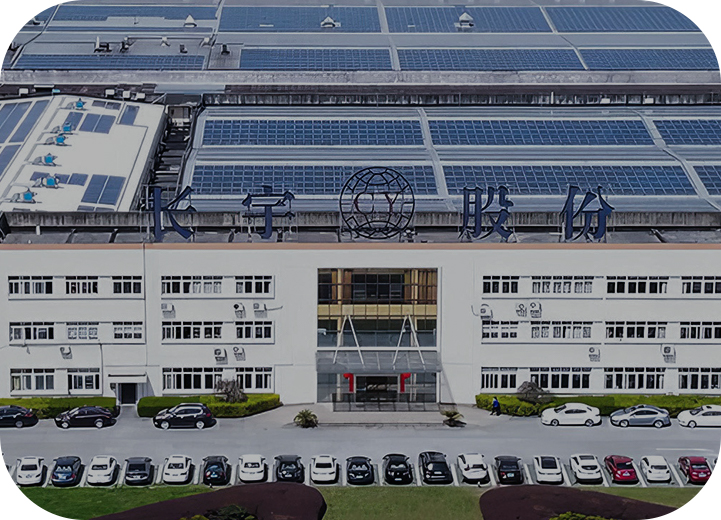

Zhejiang Changyu New Materials Co., Ltd.

Established in April 2000, Zhejiang Changyu New Materials Co., Ltd.,

is a

We have about 350 employees and the factory covers an area of 40,000 square meters. Our main products include VMPET, VMCPP, VMBOPP, PVDC coated film, Acrylic coated film, ALOx PET film.

VIEW MORE

professional manufacturer of high barrier metalized polyester films, coated film, ALOx PET film in China

. We keep stable cooperation with famous enterprises like Amcor, Bemis, Zijiang.We have about 350 employees and the factory covers an area of 40,000 square meters. Our main products include VMPET, VMCPP, VMBOPP, PVDC coated film, Acrylic coated film, ALOx PET film.

Understand Us

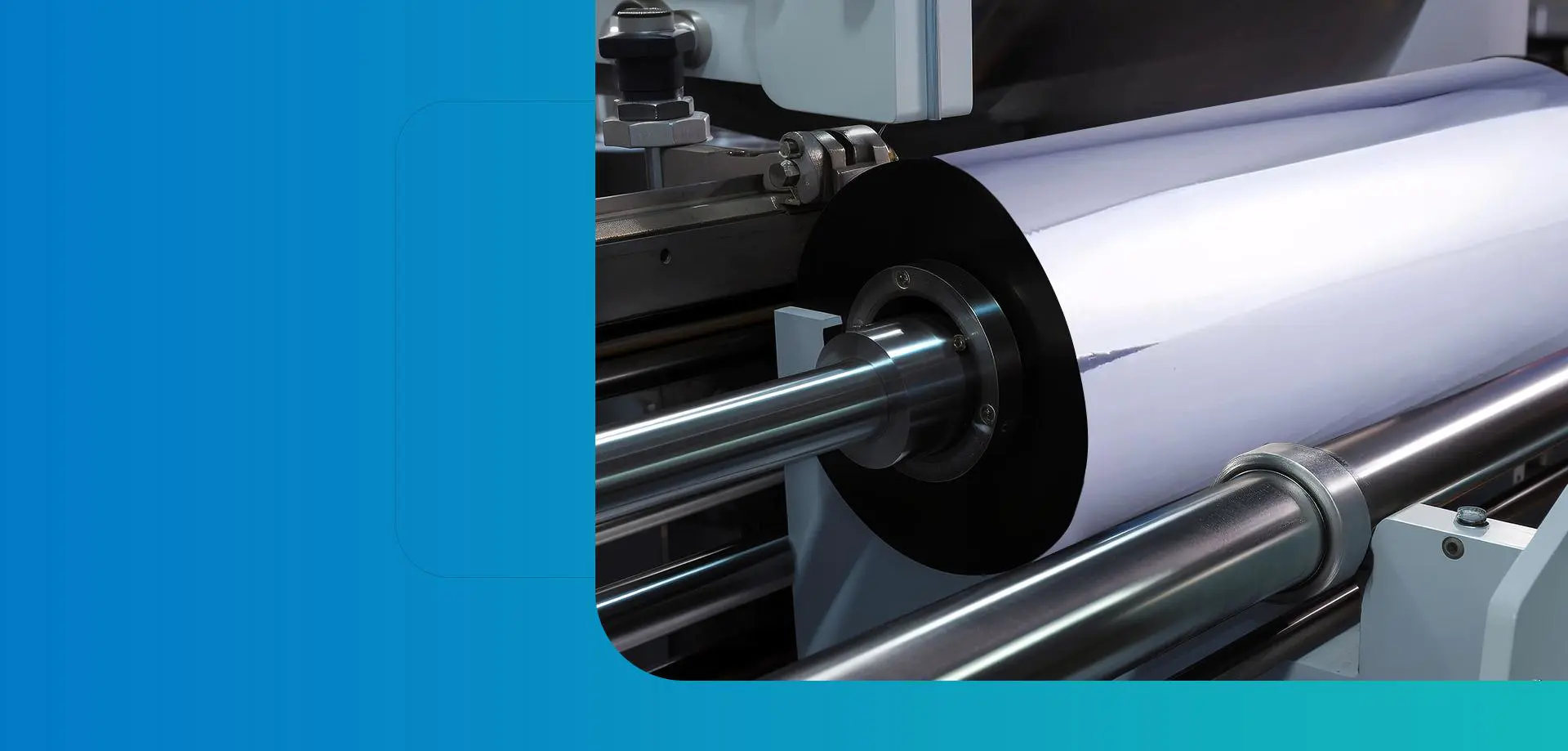

Advanced Production Equipment

16 metallizing equipment and 5 coating equipment, our annual output is 100,000 MT various metallized film and 8,000 MT coated film. The introduction of alumina equipment and crucible metalizer from Germany are committed to the development of high-end products.

FACTORY

What Sets Us Apart

-

CapacityOver 100,000MT

CapacityOver 100,000MT -

Equipment16 metallizing +5 coating

Equipment16 metallizing +5 coating -

Comprehensive productsInnovation products

Comprehensive productsInnovation products -

Rich experience25 years of industry experience

Rich experience25 years of industry experience -

Brand effectGood reputation

Brand effectGood reputation -

Trends of the industryCooperation with well-known enterprises

Trends of the industryCooperation with well-known enterprises -

Quality controlEnsure product quality

Quality controlEnsure product quality -

Excellent serviceResponsible for customers

Excellent serviceResponsible for customers -

Group advantageProvide professional guidance

Group advantageProvide professional guidance

News information

Update News

English

English  中文简体

中文简体