ALOx Films Manufacturers

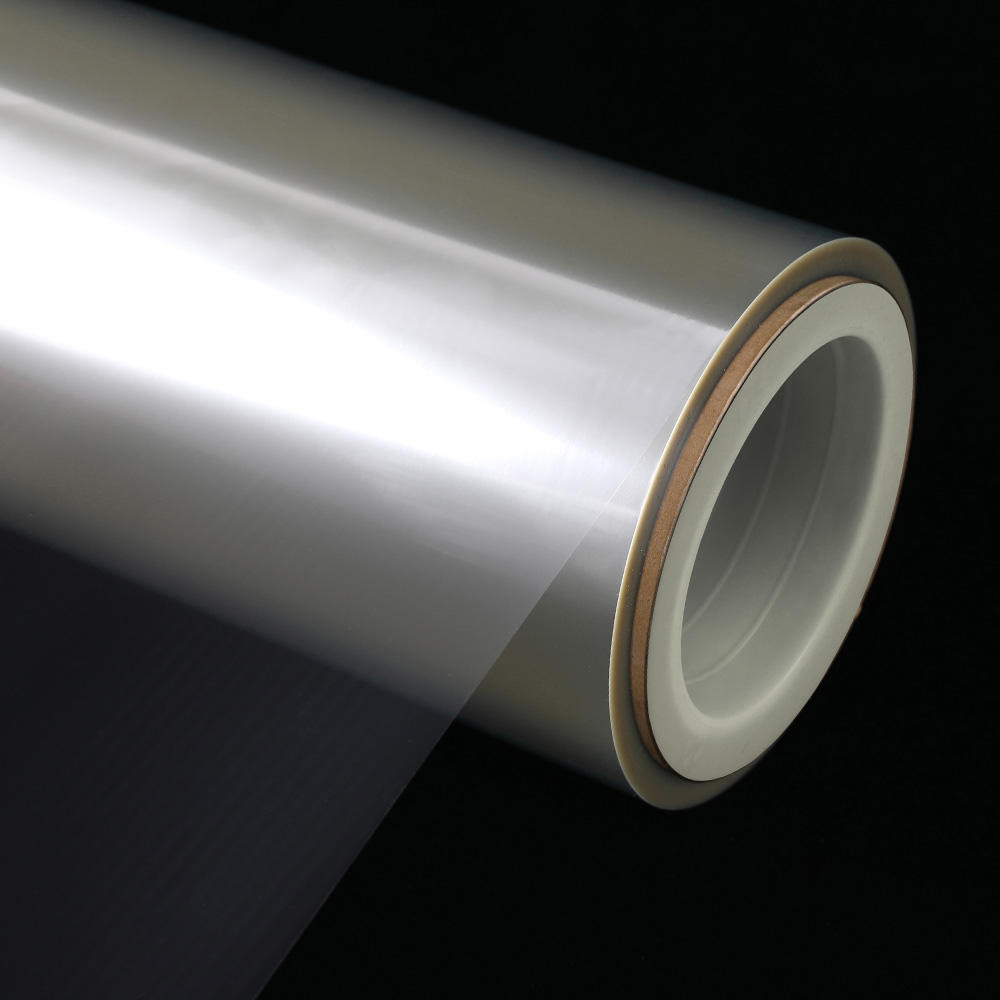

Alox film is coating a thin and highly transparent aluminum oxide on packaging films, making the materials have extremely high moisture and gas barrier properties, far to those provided by other transparent flexible packaging materials like PVDC coated film and EVOH coextrusions, rivaling those of aluminum foils and metalized films. Furthermore, moisture and gas permeabilities are not affected by high levels of temperature or relative humidity and are independent of the base film thickness thus enabling downgauging of packaging materials. It is the only flexible material have both high barrier and transparent properties, which could extend the shelf life and packaged product to be clearly visible.

Alox film is microwavable, this is what aluminum foils and metalized films can not do. As they can be retorted as well, this makes them ideally suited for the packaging of processed foods that can be microwave heated or cooked in the pack itself before consumption. And it is sustainable, eco-friendly, and printable and can be widely used for food packing, like biscuits, snacks, pet food, and so on, Electronics packaging, paper-based liquid containers packagings, retort pouch, and microwave packaging, medicine packaging, cosmetics packaging, mask packaging, etc.

English

English  中文简体

中文简体