How to avoid the problem of aluminum coating transfer?

1. Replace with better quality aluminized film. (Recommend the film from Zhejiang Changyu)

2. Replace with a suitable adhesive, preferably aluminized film special adhesive.

3. Appropriately increase the curing temperature and shorten the curing time, accelerate the curing reaction speed of the adhesive, prevent the adhesive from gradually penetrating into the aluminized layer of the aluminized film, and weaken the adhesion between the aluminized film base film and the aluminized layer.

4. Control the amount of glue applied, or adjust the drying temperature, ventilation, and composite line speed of the dry composite process to ensure that the adhesive is fully dried and the amount of residual solvent to be kept to a to reduce its impact on the aluminum coating.

5. Adjust the tension setting, pay attention to the tension is appropriately small, to prevent large elastic deformation of the aluminized film.

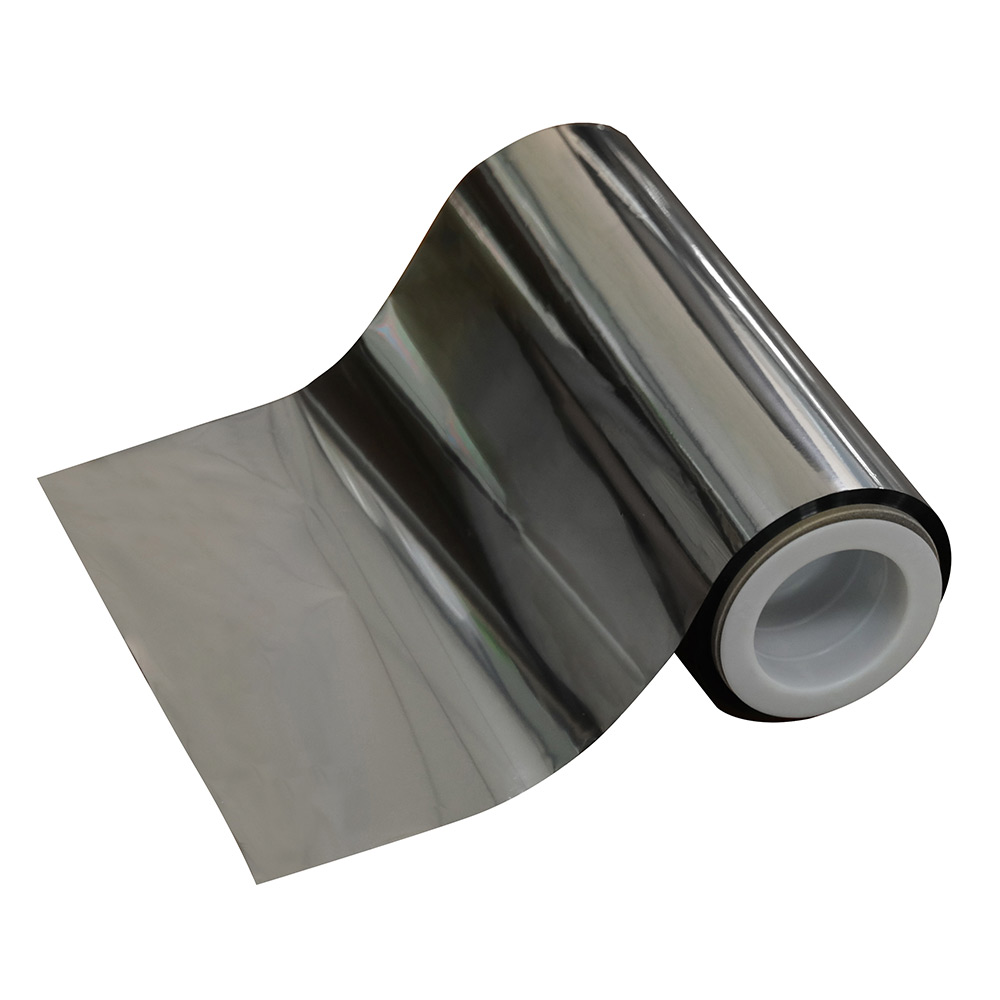

There are many types of aluminized films on the market. Our common aluminized films are OPP, CPP, PET, etc. They are divided into transfer aluminized film, laser anti-counterfeiting aluminized film, ordinary aluminized film and so on according to their use and performance. Common aluminized flexible packaging structures are: OPP/VMCPP, OPP/VMPET, PET/VMPET, VMPET/PE (CPP), etc.

English

English  中文简体

中文简体