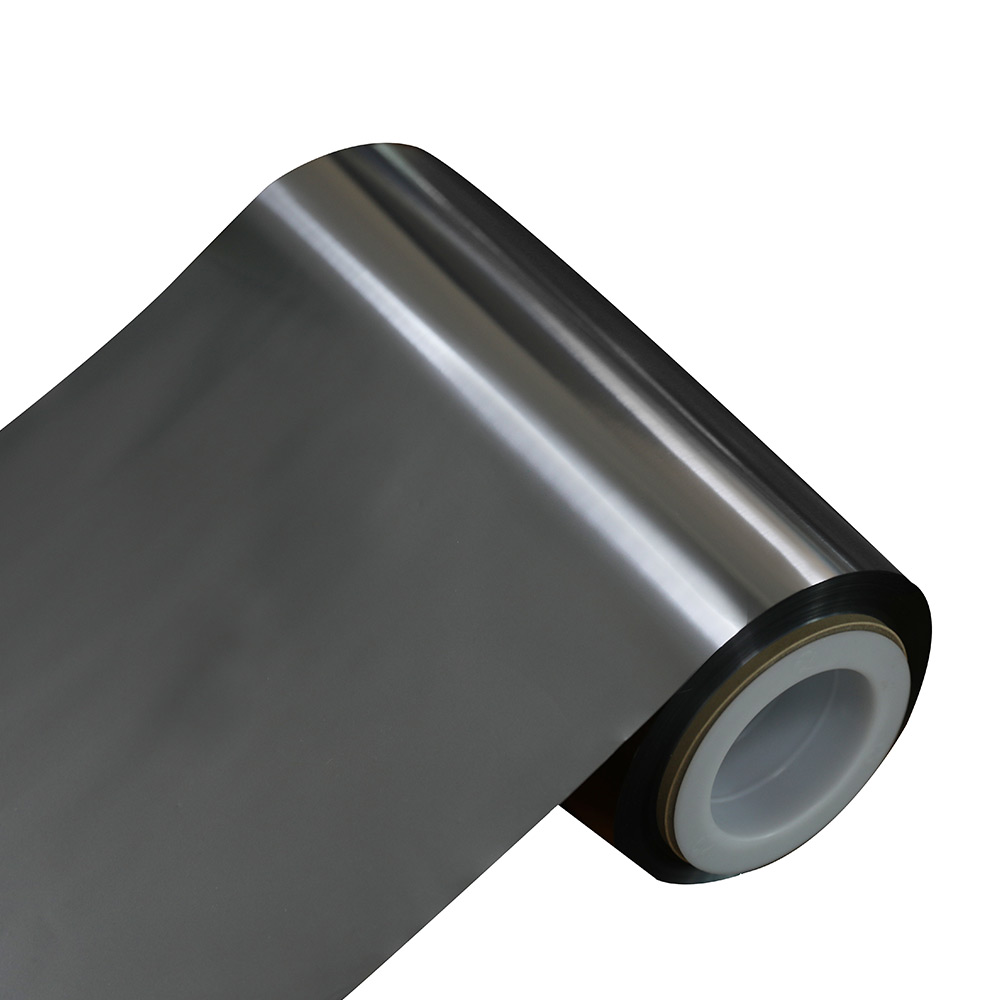

How to detect the adhesion of aluminized film?

To test the adhesion of the aluminum layer of the aluminized film, confirm the aluminum surface. The usual practical method is to use your fingers to gently scratch the front and back of the film. The film surface generally does not have obvious scratches. The aluminum layer will cause obvious scratches due to the friction of external forces.

The usual detection method of the adhesion fastness of the aluminized film is the tape detection method, that is, the 3M tape with a length of 15-20cm and a width of 0.5-1 inches is attached to the aluminum layer of the aluminum film and flattened, and then uniformly Peel the tape at a speed, observe and estimate the area where the aluminum layer is peeled off. The area is less than 10% for the level, less than 30% for the second level, and more than 30% for the third level.

The tape detection method is only a qualitative detection method, which is only suitable for general qualitative comparison. If the adhesion fastness of the aluminum plating layer exceeds the adhesive force of the tape, there will be no difference in the adhesion fastness of the aluminum plating layer. At present, the commonly used quantitative detection method is to heat seal with the EAA film (thickness 20-50um, AA content is generally around 9%) and the aluminized film layer of the aluminized film film at a certain temperature, pressure and time. The sample was cut to a width of 15 mm, and a peel test was carried out on a tensile testing machine. The size of the peel force and the area where the aluminized layer was peeled off were observed and recorded.

English

English  中文简体

中文简体