The importance of floor heating reflective film

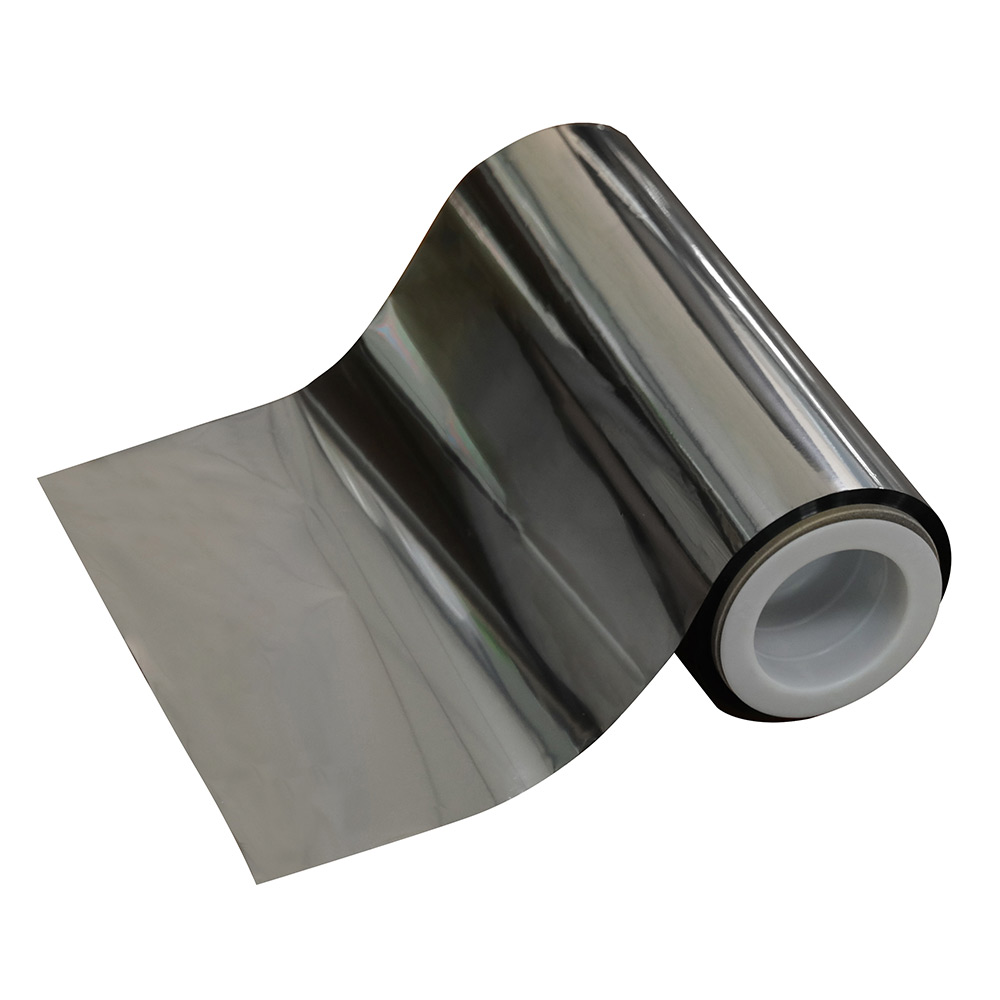

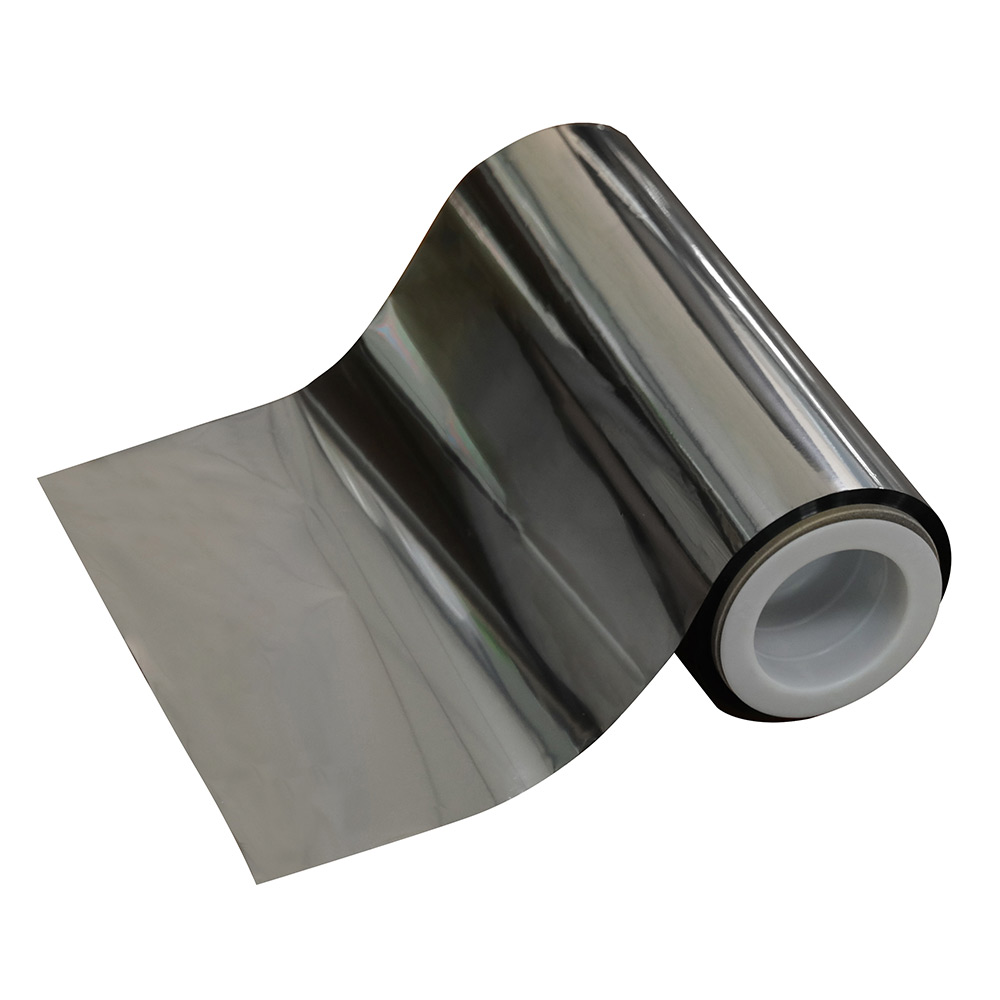

What role does our common reflective film play in floor heating systems? Do you need to lay reflective film for floor heating? In the floor heating system, EPS or XPS insulation board is usually called an insulation layer, while the reflective film is called an insulation layer, which plays the role of reflection and isolation of heat. The purpose of setting an insulation layer for low-temperature radiant floor heating is to reduce ineffective heat For multi-story and high-rise buildings, in a broad sense, in addition to the heat consumption of the enclosure structure directly or indirectly adjacent to the outdoor air, there is also heat consumption between floors in areas where floor heating is not very popular in the south. When the floor and the insulation layer are not insulated, the heat transfer medium transfers heat downward while also transferring heat downward. Due to the increase in the amount of heat transfer downward, the amount of heat transferred to it will inevitably decrease. According to heat transfer, the heat dissipation of the floor is composed of radiation and convection. For the same room, the emissivity and convection coefficients are both Constant, the heat dissipation of the floor mainly depends on the surface temperature of the floor. When the structure of the floor and the insulation layer is unchanged, it means that the heat transfer resistance is unchanged. If the diameter and spacing of the heating coil and the indoor air temperature and heat If the medium temperature is kept constant, the temperature of the upper surface of the floor cannot be changed. That is to say, at this time, the heat transfer from the floor heating is constant. As for the heat transfer from the floor heating, it is closely related to the presence or absence of an insulation layer. When there is no insulation layer, a considerable part of the heat will be transferred to the lower room through the floor slab that is not insulated or insulated. Because of the additional heat loss of this part, the room temperature will drop accordingly. This argument is not unreasonable. However, it must be pointed out that the probability of this situation in central heating areas in northern my country is not high, especially in severe cold areas. During the heating period, some users in the building are usually not allowed to completely stop heating, otherwise it will cause accidents such as pipeline freezing and cracking. . But it is very prominent in non-central heating areas in southern my country. Insulation layer is what we usually call floor heating reflective film, commonly known as aluminum foil, tin foil, but strictly speaking, it is not aluminum foil or tin foil in the true sense. In fact, it is a high-vacuum aluminized film and paper, cloth and other insulation materials. Composite products. High-vacuum aluminum film is made of plastic films such as PET, BOPP, CPP, etc., under high vacuum and high temperature, aluminum molecules volatilize and naturally adhere. It is characterized by protection from light, heat preservation, and heat reflection. Floor heating reflective film can be divided into three categories according to the substrate: paper-based film, cloth-based film, and thermal insulation composite film. The characteristic of the floor heating reflective film is that the high-quality reflective film should be a product made of high-quality PET aluminized film, paper, cloth, and insulation materials. The PET aluminized reflective film has high brightness, strong bonding, no aging, and no dealumination. , No hot stamping, etc., is the choice for the production of reflective film materials, followed by BOPP and CPP. In fact, this is a substitute. The reflective film produced with this aluminized film has indicators such as brightness, firmness, and aging period. Both are worse than PET aluminized film. www.hncypacking.com

English

English  中文简体

中文简体