What are the advantages and uses of both sides PVDC coated PET film in the food packaging industry?

Both sides PVDC (Polyvinylidene Chloride) coated PET (Polyethylene Terephthalate) film offers several advantages and finds numerous uses in the food packaging industry. Here are the key advantages and common applications of both sides PVDC coated PET film:

Advantages of both sides PVDC coated PET film:

Excellent Barrier Properties: PVDC coating provides exceptional barrier properties against moisture, oxygen, and other gases. The coating forms a protective barrier on both sides of the PET film, preventing the penetration of moisture and oxygen, and maintaining the freshness and quality of the packaged food products.

Aroma and Flavor Preservation: Both sides PVDC coated PET film helps to retain the aroma and flavor of the food products. It prevents the loss of volatile compounds and protects the food from external odors, ensuring that the original taste and scent of the food are preserved.

Oil and Grease Resistance: The PVDC coating enhances the film's resistance to oil and grease, making it suitable for packaging oily or greasy food products. It prevents oil and grease from seeping through the packaging, maintaining its integrity and appearance.

Temperature Resistance: PVDC coated PET film has good temperature resistance, allowing it to withstand hot and cold temperatures. This makes it suitable for both refrigerated and microwaveable food packaging applications.

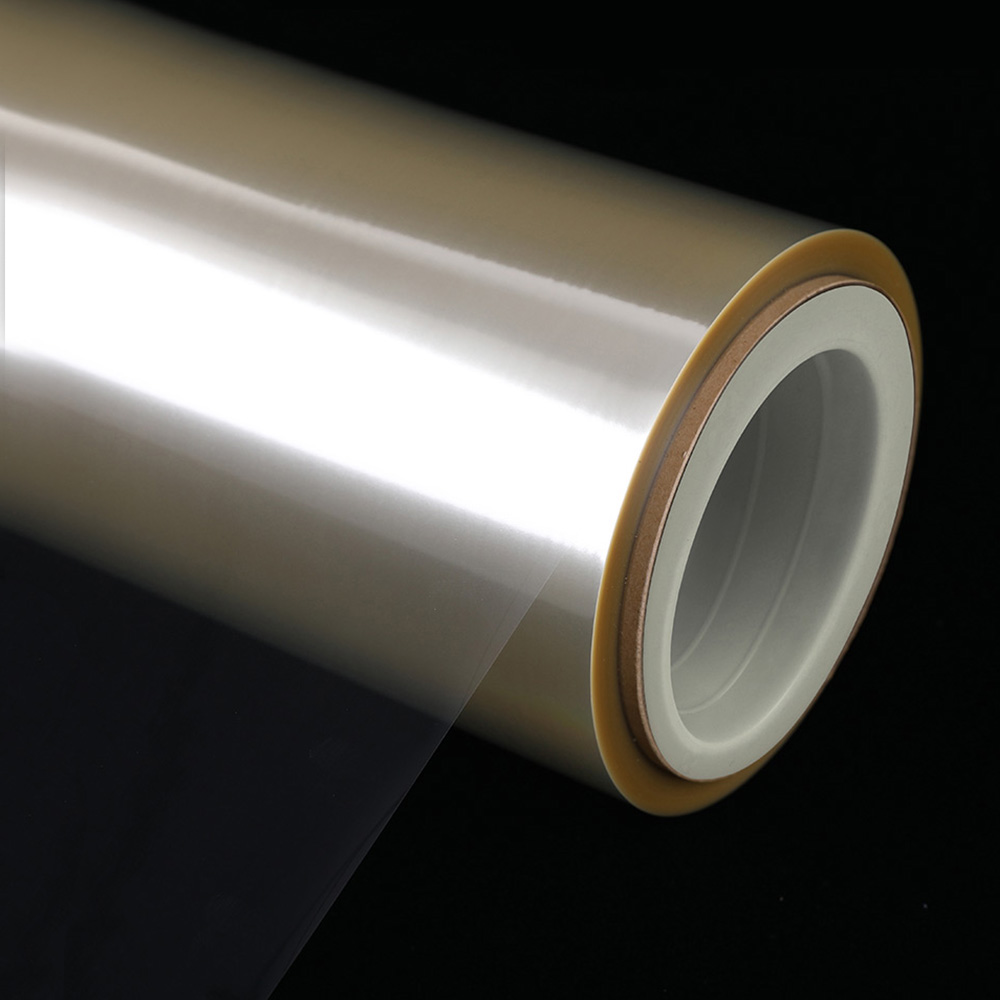

Clarity and Transparency: The PET film base provides clarity and transparency, allowing consumers to see the packaged food products. The PVDC coating does not compromise the visual appeal of the packaging, making it visually appealing to consumers.

Uses of both sides PVDC coated PET film in the food packaging industry:

Snack Food Packaging: Both sides PVDC coated PET film is widely used for packaging snack foods such as chips, biscuits, cookies, and nuts. It helps to preserve the crispness and freshness of the snacks while providing an attractive and transparent packaging solution.

Confectionery Packaging: The barrier properties of both sides PVDC coated PET film make it suitable for packaging confectionery items like chocolates, candies, and chewing gums. It protects the confectionery from moisture, oxygen, and odor, ensuring the quality and taste of the products.

Bakery Product Packaging: It is commonly used in the packaging of bakery products such as bread, pastries, and cakes. The barrier properties of the PVDC coating help to extend the shelf life of the bakery items and maintain their freshness.

Ready-to-Eat Meals Packaging: Both sides PVDC coated PET film is used for packaging ready-to-eat meals, including pre-cooked or pre-packaged meals. It provides a barrier against moisture and oxygen, ensuring the quality and taste of the food.

Dairy Product Packaging: It finds applications in packaging dairy products such as cheese, butter, and yogurt. The PVDC coating helps to prevent moisture and oxygen from affecting the quality and texture of the dairy products.

These are some of the advantages and uses of both sides PVDC coated PET film in the food packaging industry. Its barrier properties, aroma and flavor preservation, oil and grease resistance, temperature resistance, and clarity make it a preferred choice for preserving the quality and freshness of various food products.

English

English  中文简体

中文简体