What are the application environment and bonding requirements of PE protective film?

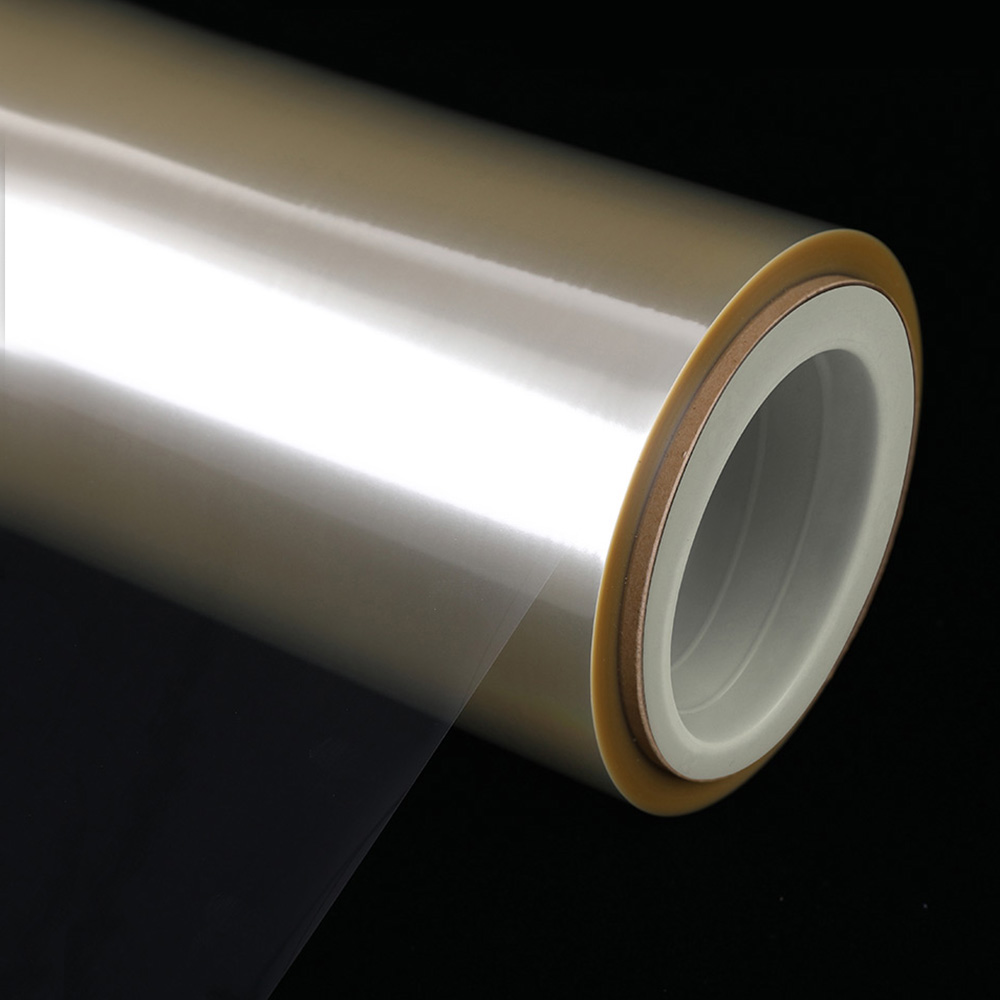

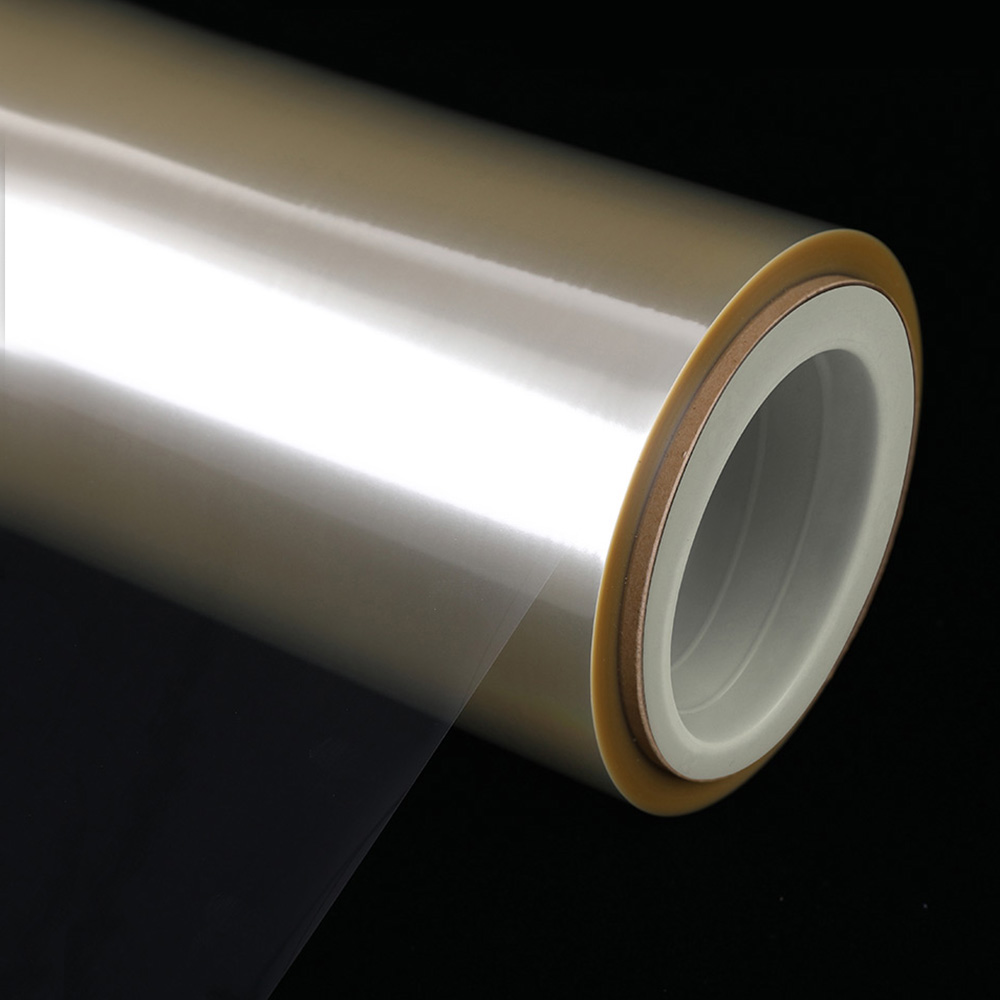

In order to prevent the surface migration of electrostatic materials, PE protective film is non-toxic, odorless, environmentally friendly and has a good effect. Therefore, this protective film can be used in packaging materials, inserts and displays to achieve the desired effect. PE protective film uses glue in the production process, generally there are two kinds of silica gel and acrylic glue, and the choice is mainly determined by the bonding requirements. Highly transparent PET protective film is a kind of PET protective film, which has the influence of silicone system and OCA system on glue. The difference between the two is mainly in curing. The former is thermally cured, and the latter is fixed on UV. The PE protective film performs well in the middle after using for a period of time, but the two ends of the product will rise. The main reason is that the protective film and the protective layer stretch to a large extent during the bonding process, and there is unnecessary shrinkage in the high temperature environment. In the production process, the PE protective film should effectively pay attention to the impact of its environmental temperature difference on the use of the product, and avoid unnecessary surface tension during the pasting process. When the user installs and constructs the profile, the protective film needs to be removed from the surface of the profile. www.hncypacking.com

English

English  中文简体

中文简体