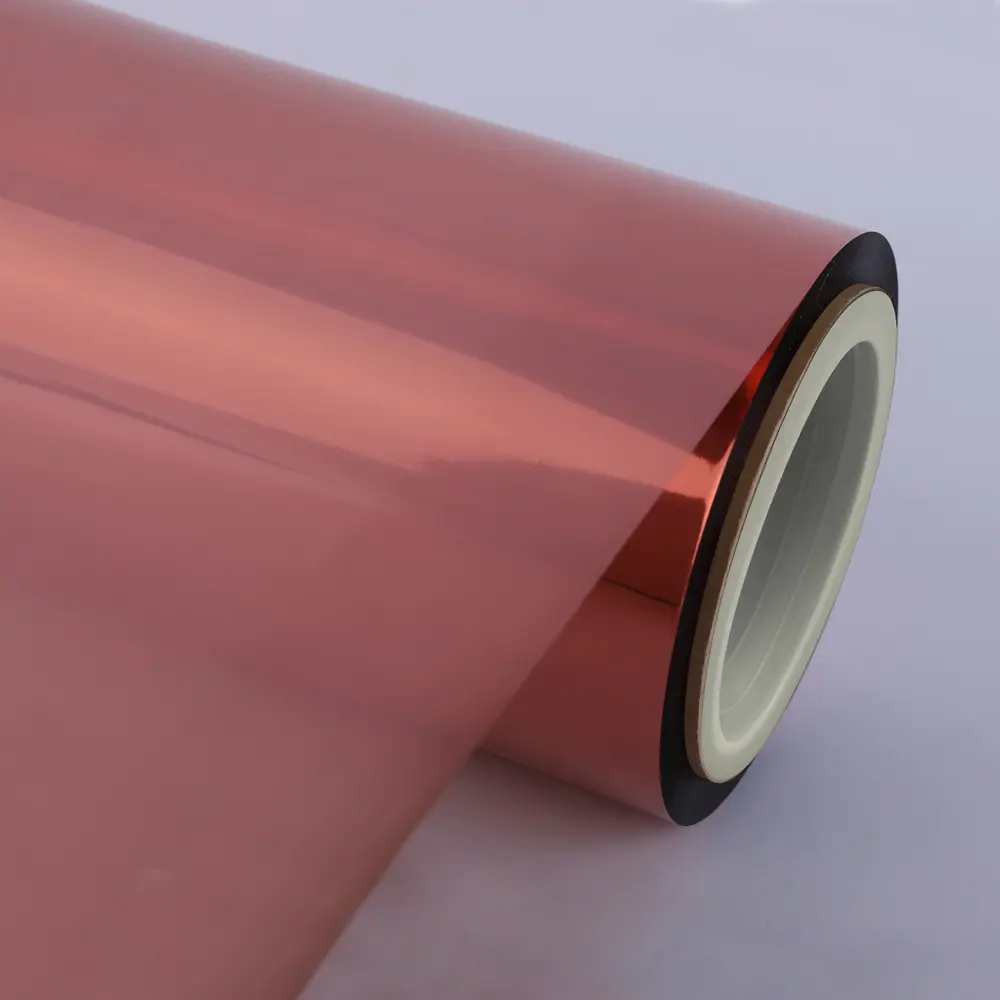

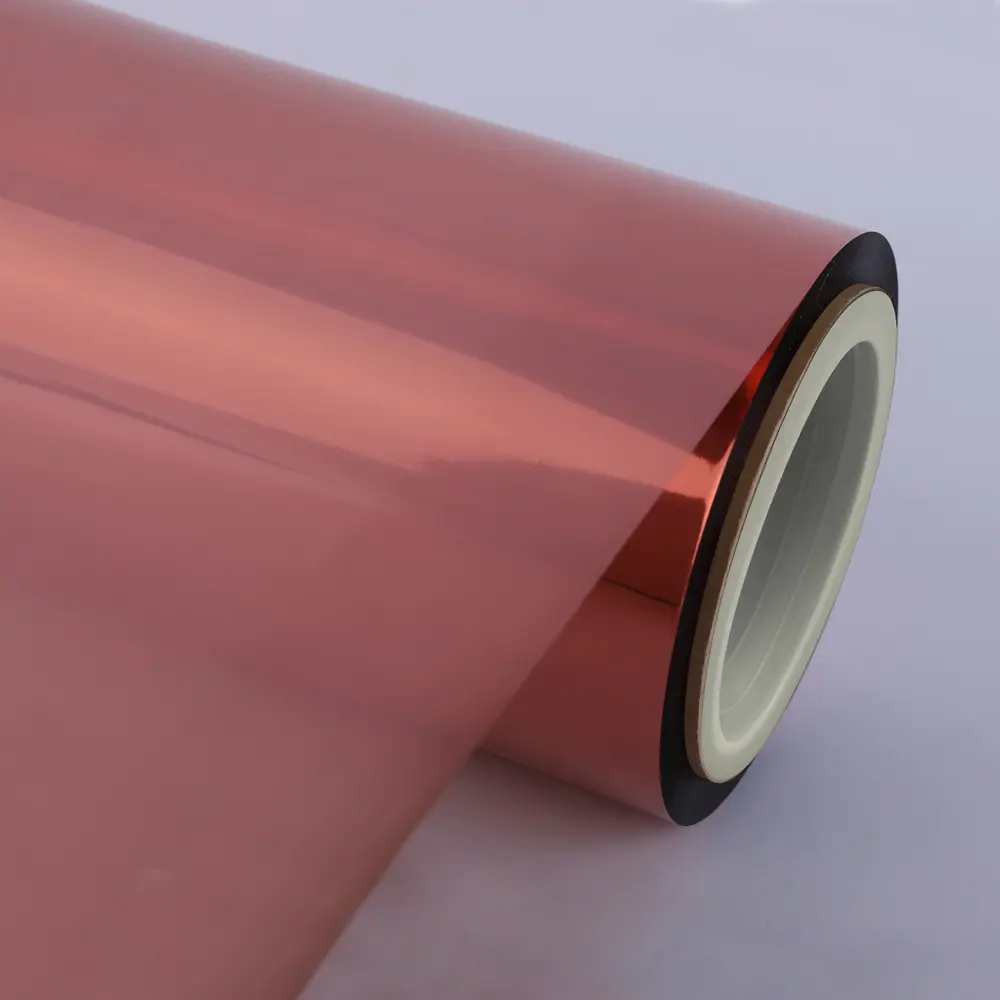

What are the benefits of high-barrier metallized films?

High barrier metallized film provides the ideal solution when taste and fragrance need higher protection from air and volatile oil concentration. Low vapor barrier prevents airborne particles, oil droplets, dust and other impurities from settling in the film and thus enhancing its durability. Vacuum Metallizing of PET film is an established technique to obtain special optical characteristics and minimize the absorption of flavors and gases through the film. The barrier metallized film is made of plastic. It has low structural distortion and chemical and physical properties. It is known to have similar durability and thermal conductivity as stainless steel. Due to its unique mechanical and optical properties, the high barrier metallized film is utilized for automotive, pharmaceutical, cosmetic, aerospace, and defense applications. This film can resist high temperatures and weather conditions. It is also resistant to acid and chlorine. It is used for packaging of hazardous agents and flammables. It is available with an outstanding adhesive quality and mechanical and optical properties, due to which it has immense potential use. The invention is comprised with an improved method of coating the surface, which results in the formation of a thin film that imparts protection to the surface upon application. This film can also achieve machinability and thermal conductivity. High barrier metallization is preferred form of protection against abrasions, cuts, and nicks which are commonly found in today's world. It can resist more chemicals and liquids for effective resistance. This invention has another important feature of overcoming oil spills, which have badly affected many people. It is also highly useful for preventing corrosion and thus is ideal for electrical insulating components. It has chemical, physical and optical properties, which make it an ultimate solution for various industries. High barrier polyethylene film has good thermal conductivity, chemical and physical properties. It is preferred form of packaging in the food and drug industries and it has very good resistance to alkalis and acids. This invention is comprised with the method of using high temperature to bond the two polymer layers and this provides chemical, physical and optical properties to the polyester film. It can withstand more of the chemicals, liquids and alkalis and is available in an easy to use, customized form. It is very advantageous for application in several industries. This product can resist heat, abrasion, pressure, oil, grease, dirt and grease and it is used for various applications. www.hncypacking.com

English

English  中文简体

中文简体