What are the permeability and structural requirements of PE protective film?

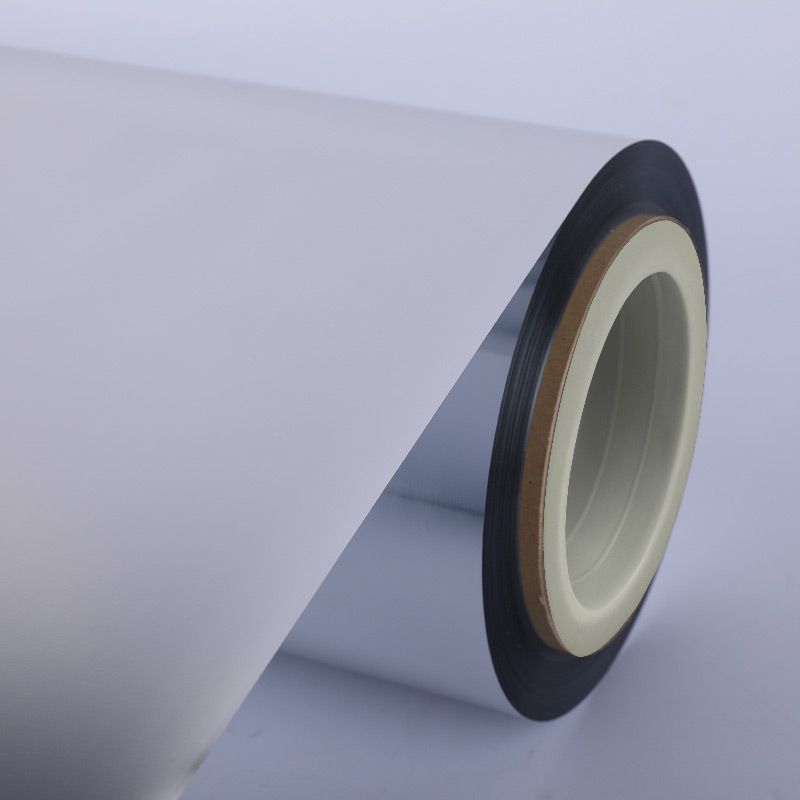

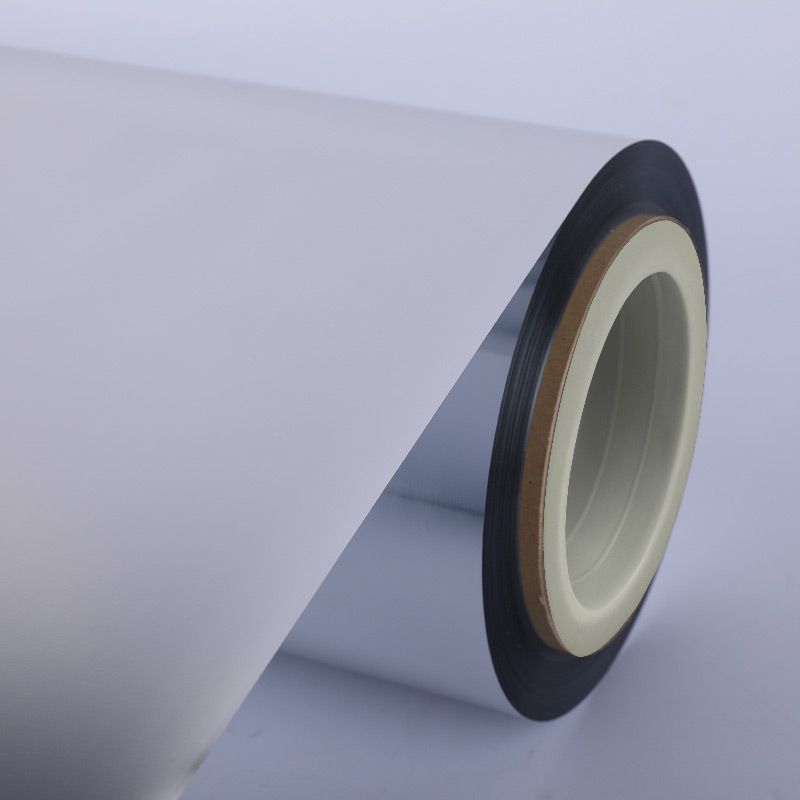

Everyone knows that PE protective film can be seen everywhere in life. PE protective film is generally used in photoelectric industry, plastic industry, printing industry, etc. So, do you know much about the permeability and structural requirements of PE protective film? The PE protective film adopts a three-layer anti-scratch and anti-electromagnetic radiation structure during the production process. The thickness of the protective film is about 0.25mm, which is anti-reflective, anti-electromagnetic radiation, and effectively filters ultraviolet rays. Electrostatic adsorption technology, without glue, can be pasted multiple times. Extremely high abrasion resistance, scratch resistance, and durable. The light transmittance reaches 99%, and the picture is clear and vivid. The PE protective film effectively adopts a three-layer structure, and its surface layer is a frosted layer, which can effectively resist fingerprints during use. Under normal circumstances, the finger will not leave marks when sliding over, even if it leaves sweat and other liquid residues, only It can be cleaned by swiping lightly by hand, which guarantees the visual effect of the screen to a greater extent. The material is processed by a special process, which can effectively prevent reflection and reduce the problem of reflection of the screen in the sun or waiting. The PE protective film material has a higher permeability. As a liquid crystal screen protective film material, it has no visual obstacles, impact resistance, and good mechanical properties. The impact strength is 3-5 times better than other materials. It is resistant to oil and dilute acid. , Dilute alkali, and other solvents. PE protective film has good weather resistance, lower resistance to low temperature of minus 70 degrees, higher than 150 degrees, prevents water vapor penetration, has a good water vapor barrier function! Powerful protection performance, environmentally friendly material, non-toxic and pollution-free, is a real safe material. The PE protective film will be inert to the surface of the protected material during use, and the product has good adhesion to the protected material. In the process of material handling and processing, the protective film will not warp or fall off; the protective film has Good weather resistance and sticking stability. After several days or long pasting, the peeling force does not increase significantly, and it is easy to remove. There is no residual glue on the protected surface when it is removed, and there is no shadow. www.hncypacking.com

English

English  中文简体

中文简体