What are the quality requirements and working temperature of PE protective film?

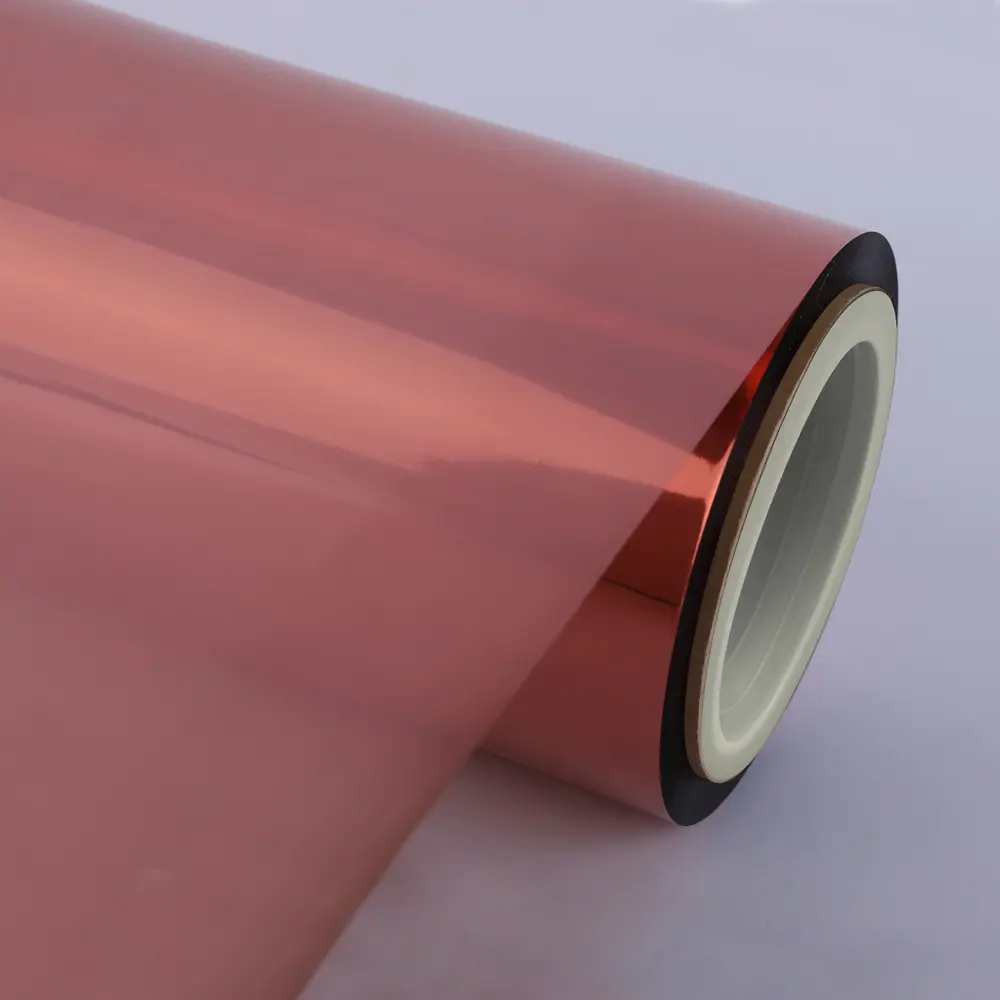

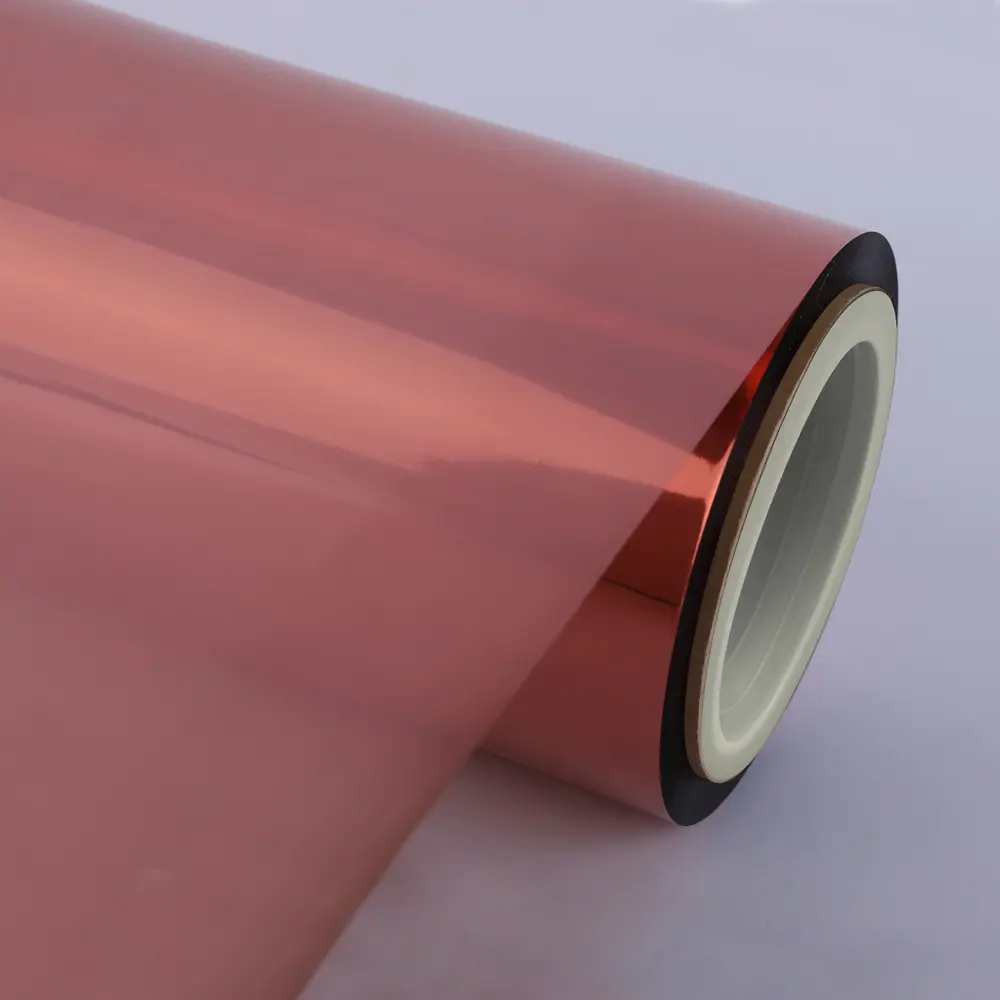

The quality requirements and working temperature of PE protective film. When PE protective film is used in computer engraving and other advertisement production, the effect of oil glue is that the engraved characters and patterns are not easy to deform, and are suitable for long-term posting and falling off. Such products, such as instant stickers, furniture stickers, stickers, etc. The quality requirements of PE protective film can be summarized as three points. 1. No degumming is required. After the glass processing is completed, when the maintenance film is removed, no glue or traces should be left on the surface of the processed glass product to keep the product bright and beautiful. 2. Good strength and toughness means that the mask can withstand the impact of spraying silicon carbide up to 6×8 kg, otherwise it will break through the repair film and break through the processing object. 3. With proper adhesion, the film on the finger surface can not only be attached to the glass body to be maintained and firmly attached to it, but also can be smoothly removed after processing, so as not to increase the brittleness and slender fracture and Unnecessary trouble caused by tearing. 4. The color and specifications of the repair film can be customized according to the user's requirements. The commonly used colors are white and yellow, and the length is in meters, which can be customized according to the user's requirements. The quality of the maintenance film directly affects the working time and product quality. PE protective film has high temperature resistance. PE protective film is widely used in food packaging and protective film, and it is also very common in life. In the traditional packaging, the general food industry and the pharmaceutical industry use a large number, and the packaging used in the past has great environmental pollution. Life is basically using PE protective film for food packaging and preservation. PE protective film is usually in two temperature states, one is low temperature and the other is high temperature. www.hncypacking.com

English

English  中文简体

中文简体