What is the process flow of aluminum coating?

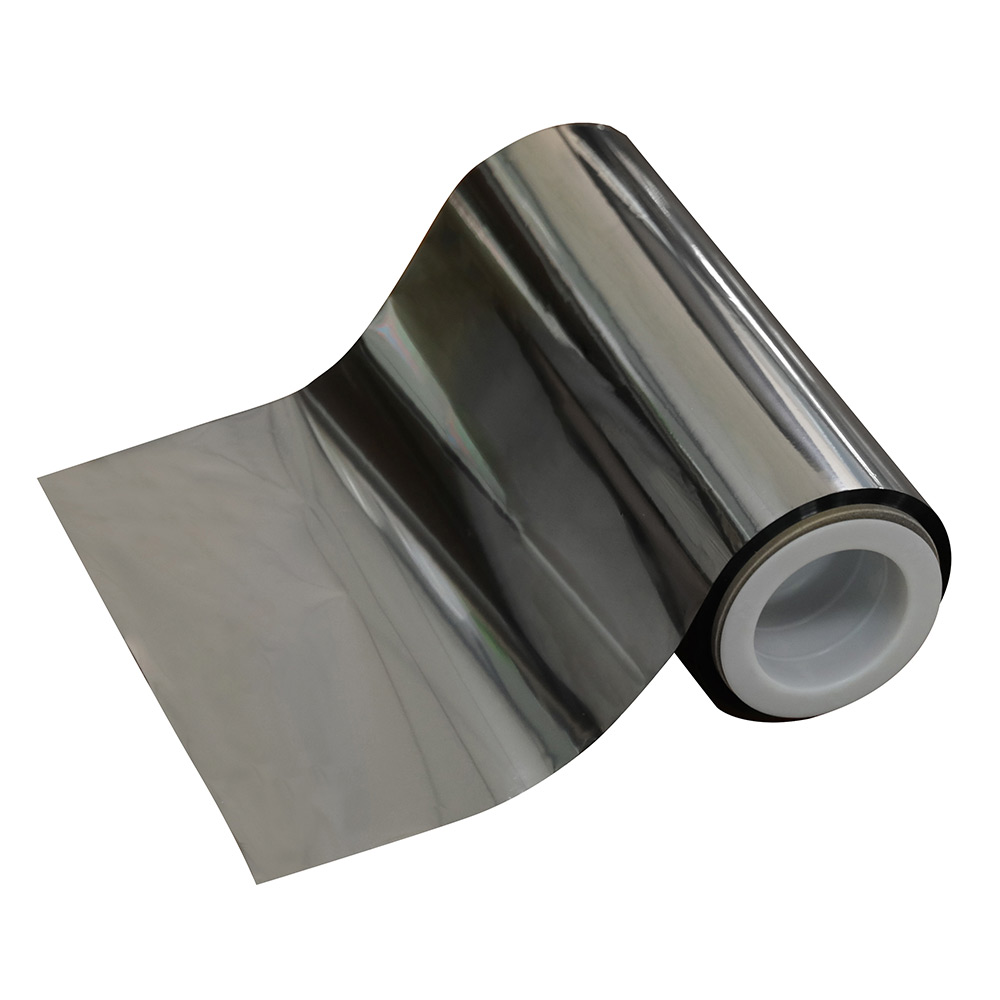

The aluminum plating process of plastic thin aluminum plastic bags generally adopts the direct plating method, that is, the aluminum layer is directly plated on the surface of the substrate film. BOPET and BOPA film substrates do not need surface treatment before aluminum plating, and can be directly evaporated. For non-polar plastic films such as BOPP, CPP, PE, etc., the surface of the film needs to be corona treated or coated with an adhesive layer before evaporation to make the surface tension reach 38-42 dynes/cm or have good adhesion . During vapor deposition, place the roll film in the vacuum chamber and close the vacuum chamber to evacuate. When the vacuum reaches a certain level (above 4×10-4mba), the evaporation boat is heated to 1300℃~1400℃, and then the aluminum wire with a purity of 99.9% is continuously sent to the evaporation boat. Adjust the unwinding speed, winding speed, wire feed speed and evaporation amount, and turn on the cooling source to make the aluminum wire continuously melt and evaporate on the evaporation boat, so that a bright aluminum layer is formed after the moving film surface is cooled. It is aluminized film.

English

English  中文简体

中文简体